Cerca nel sito

WHAT IS THE BEST SOLUTION FOR COOLING IN SUPER FAST CHARGING SYSTEMS?

The future of private and public mobility will be more and more electric, as evidenced by the offer of car manufacturers increasingly in zero-emission vehicles. The transition is underway, also from the point of view of infrastructure on the ground, especially in Europe where emissions regulations for internal combustion cars are becoming more and more stringent.

The evolution of solutions and the new problem

At beginning, DC charging stations allowed a power output of up to 50kW, which for end-users resulted in charging times of 30/45min, depending on battery capacity. The standard Combined Charging System (CCS) already developed to deliver charging power up to 150kW (about 15 minutes 0-100%) is undergoing important further developments in recent years to achieve the even faster charging times required by the market. This requires higher power and therefore higher currents that lead to dangerous overheating or the use of cables with a larger diameter that are not easy to handle.

What is the reference standard?

According to IEC TS 62196-3-1 connectors and charging cables can reach a maximum temperature of 50 degrees higher than the surrounding air during a charging process.

This means that the cooling unit and temperature control integrated in the charging station play a key role in the development process of these new, so-called super fast charging stations, which now reach 350kW of power output, for waiting times of about 6min.

What are the characteristics of the optimal products?

The careful selection of models and the implementation of the necessary features have led over the years to a complete range of Simaco products for this particular sector.

- Horizontal but also vertical electric pumps able to adapt to small spaces and different configurations of the cooling system, in relation to the tank, the exchanger and the pipes.

- Electric pumps with reduced vibrations, extremely silent (sound pressure < 69.5dB) to reduce noise pollution in cities detected today above 74dB.

- Operation at ambient temperatures between -20°C and +60°C to adapt to different climatic conditions in the world.

- Electropumps without mechanical seal to eliminate the risk of liquid leakage, therefore problems with the electrical circuit or loss of performance.

- Models already studied and used for several years with high efficiency motors both AC, single-phase and three-phase, and DC 24V.

- Electric pumps able to work safely with liquids with very low electrical conductivity and high density.

- Product certification for different international markets, from Europe to America.

Simaco models

Simaco is already following this path together with representatives of the automotive industry, charging infrastructure operators and other partners, and will actively participate in the future of electric mobility in the Italian European and international territory.

BRASS VERTICAL REGENERATIVE TURBINE ELECTRIC PUMPS

These are easy installation single-stage vertical brass electric pumps with immerged regenerative impeller, very easy to install and high safety, ideal for maintaining the working pressure in open circuit systems. The pumps were designed to be mounted on top of the tanks with the pump part completely immersed in the liquid, with 6 immersion depths from 100 to 200mm.

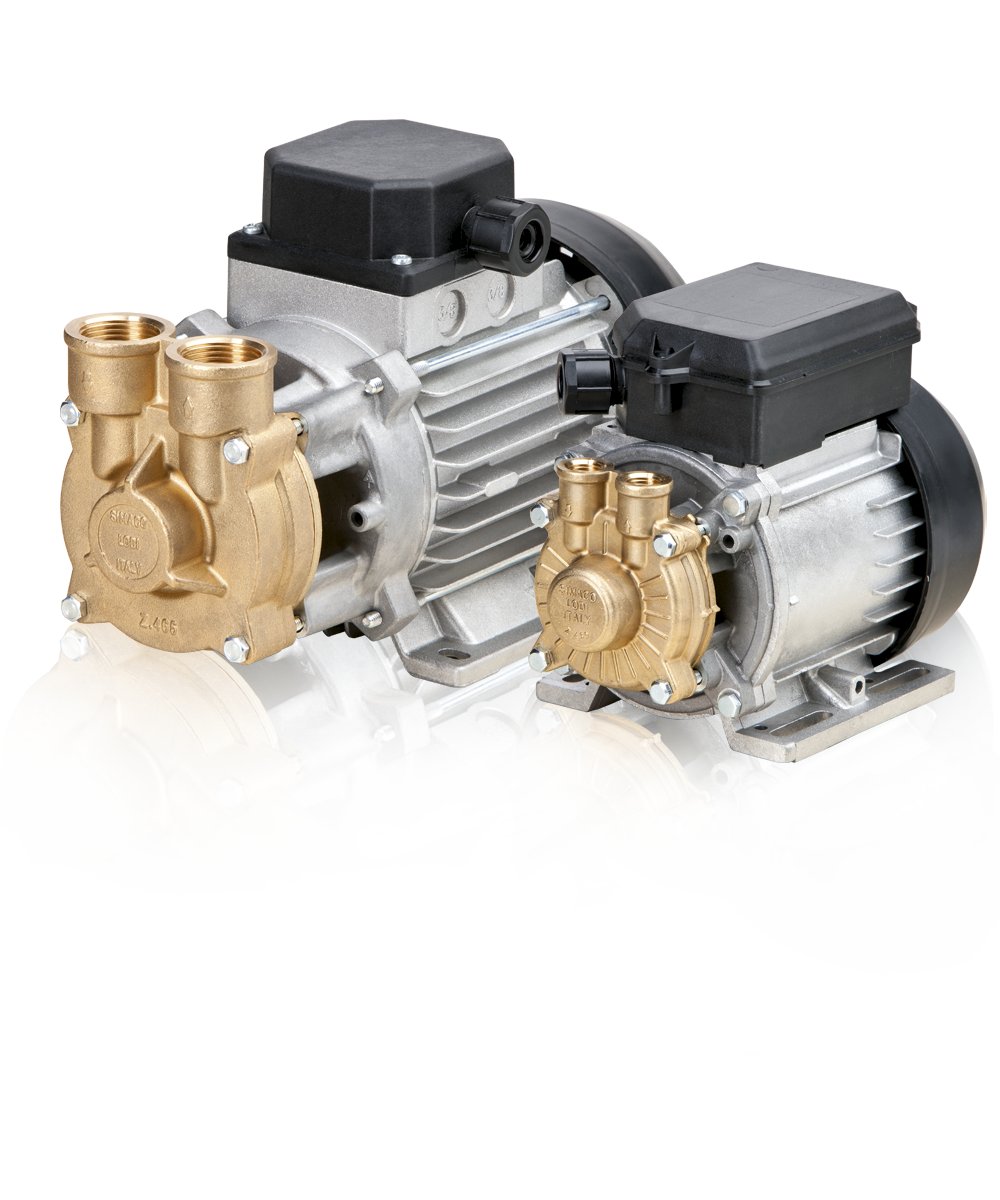

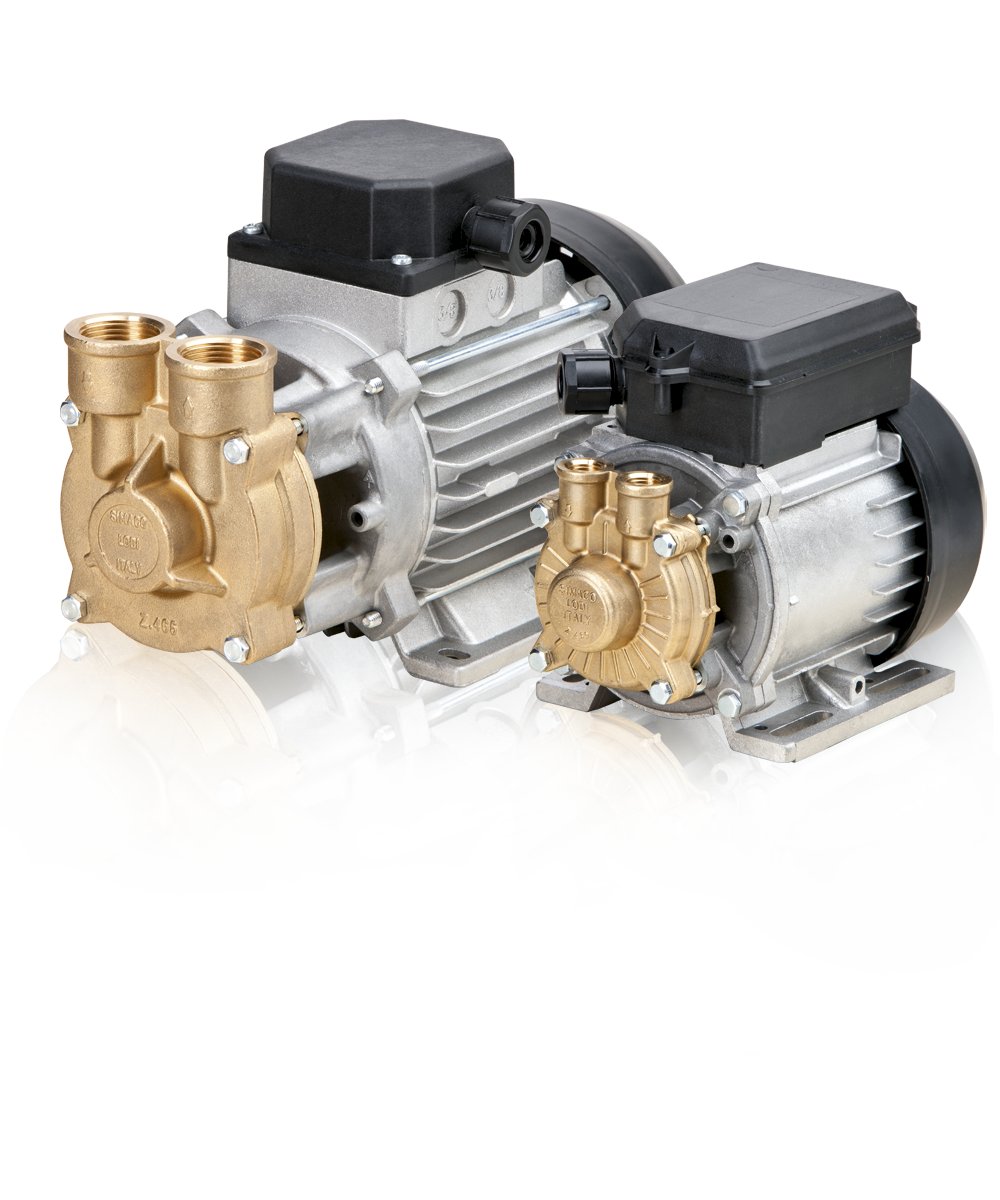

BRASS REGENERATIVE TURBINE ELECTRIC PUMPS

With pressures up to 11bar, they are suitable for use with oils, clear and clean liquids without suspended parts or abrasive parts and dilutions inert respect to the pump materials. Fluid use temperatures up to 90 ° for standard versions and 180 ° C for special versions. The selected materials guarantee a safety against the formation of rust.

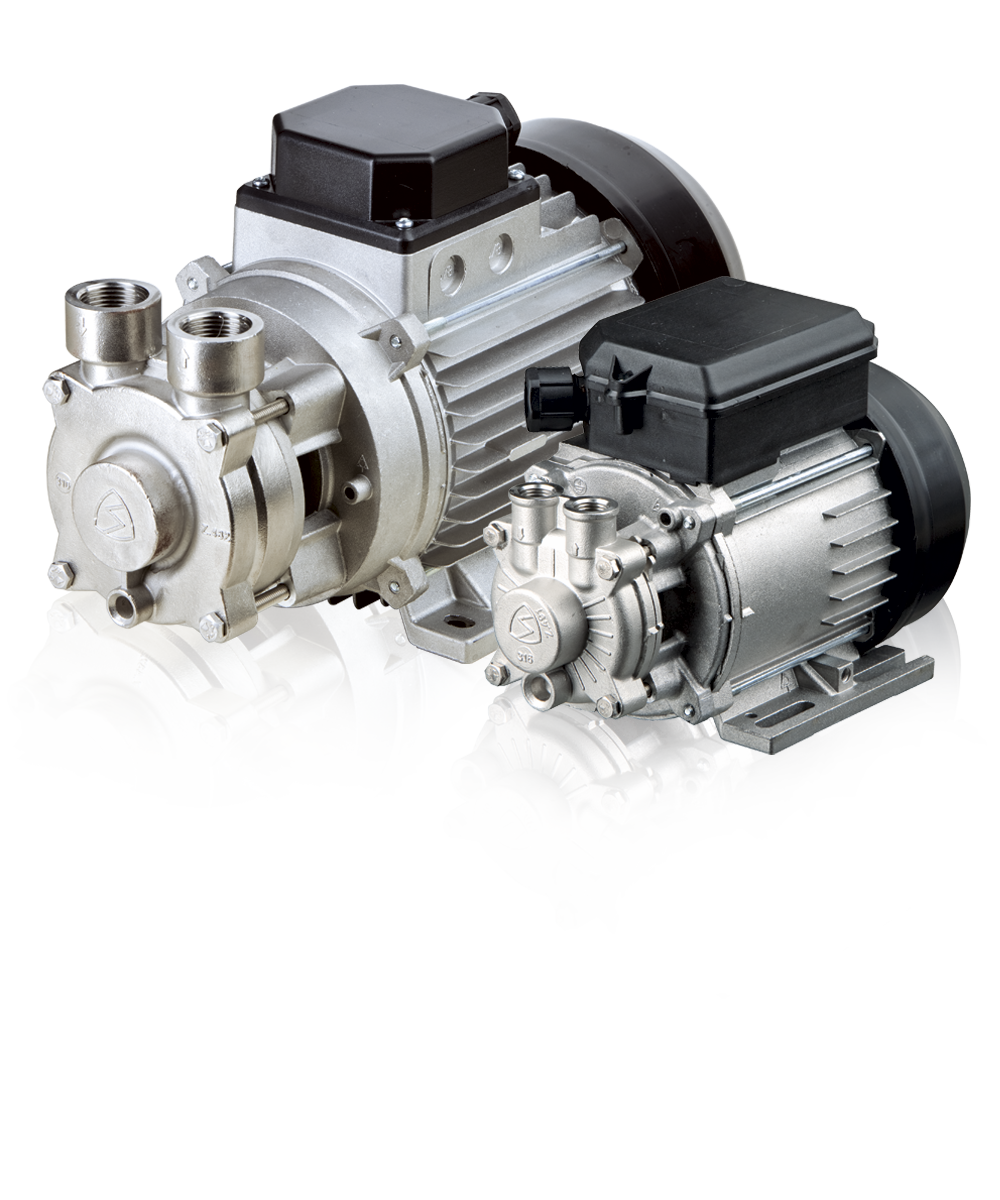

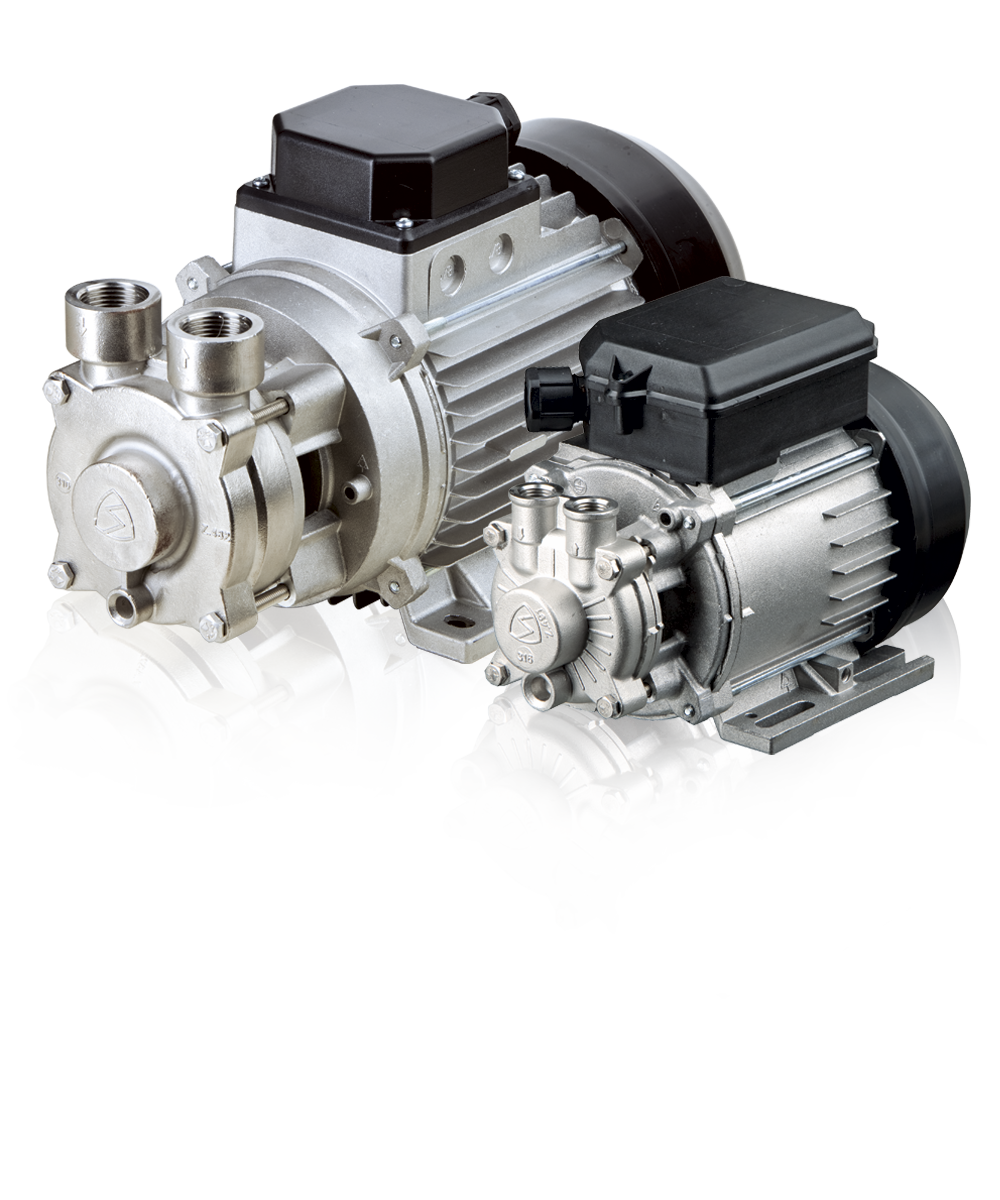

INOX REGENERATIVE TURBINE ELECTRIC PUMPS

With pressures up to 9,5bar, they are suitable for use with oils, clear and clean liquids without suspended parts or abrasive parts and slightly agressive dilutions. Fluid use temperatures up to 90 ° for standard versions and 180 ° C for special versions.

The whole range is also available in the MD version with magnetic drive, without mechanical seal, for application fields and severe conditions of use.

Write an email to your sales representative or to info@simacosrl.it for more technical or commercial information.

0

OFFICIAL DISTRIBUTORS

0

COUNTRIES SERVED

0

REGISTERED MARKS

0

EUROPEAN PRODUCT PATENTS