Cerca nel sito

KN from its origins to the present day

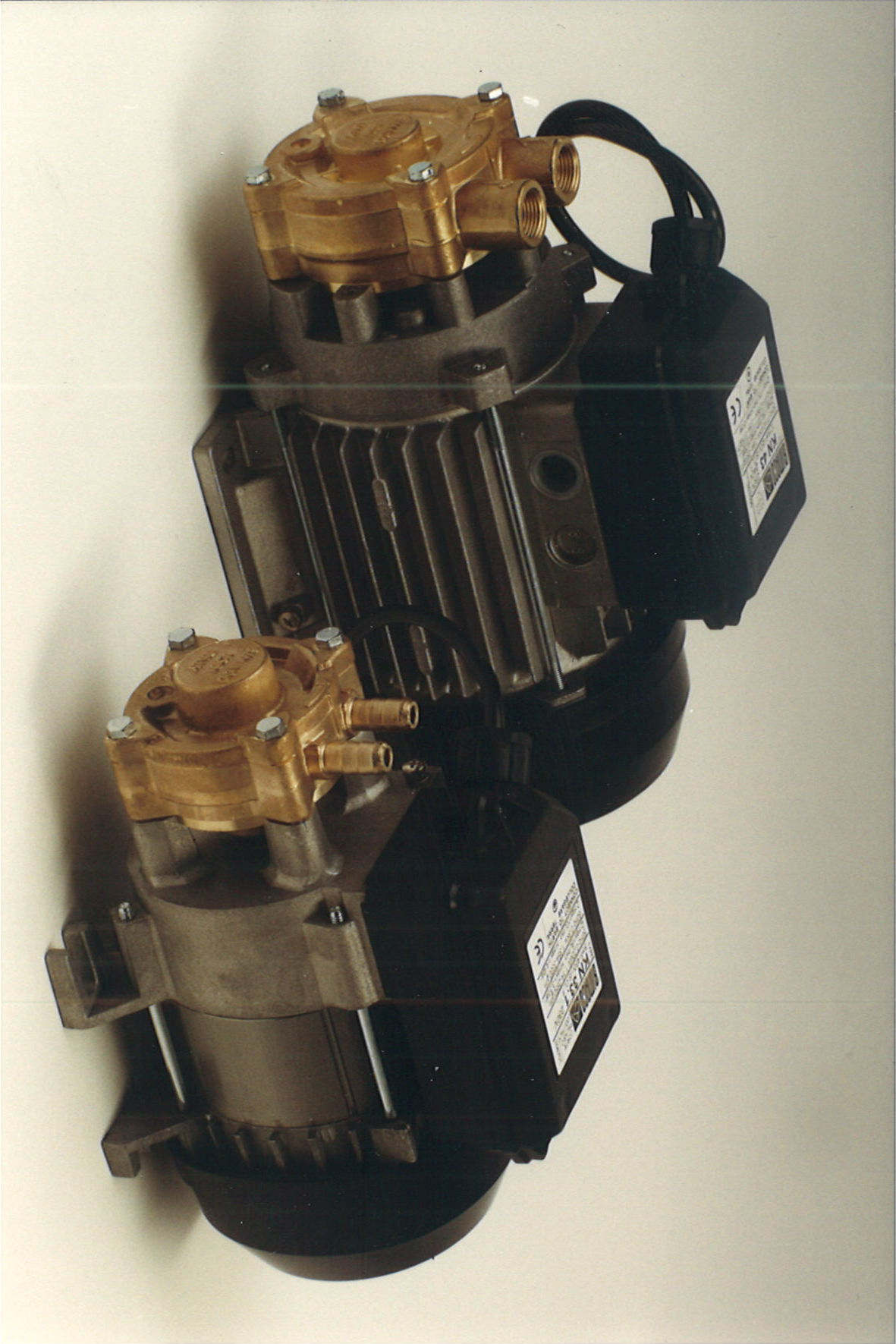

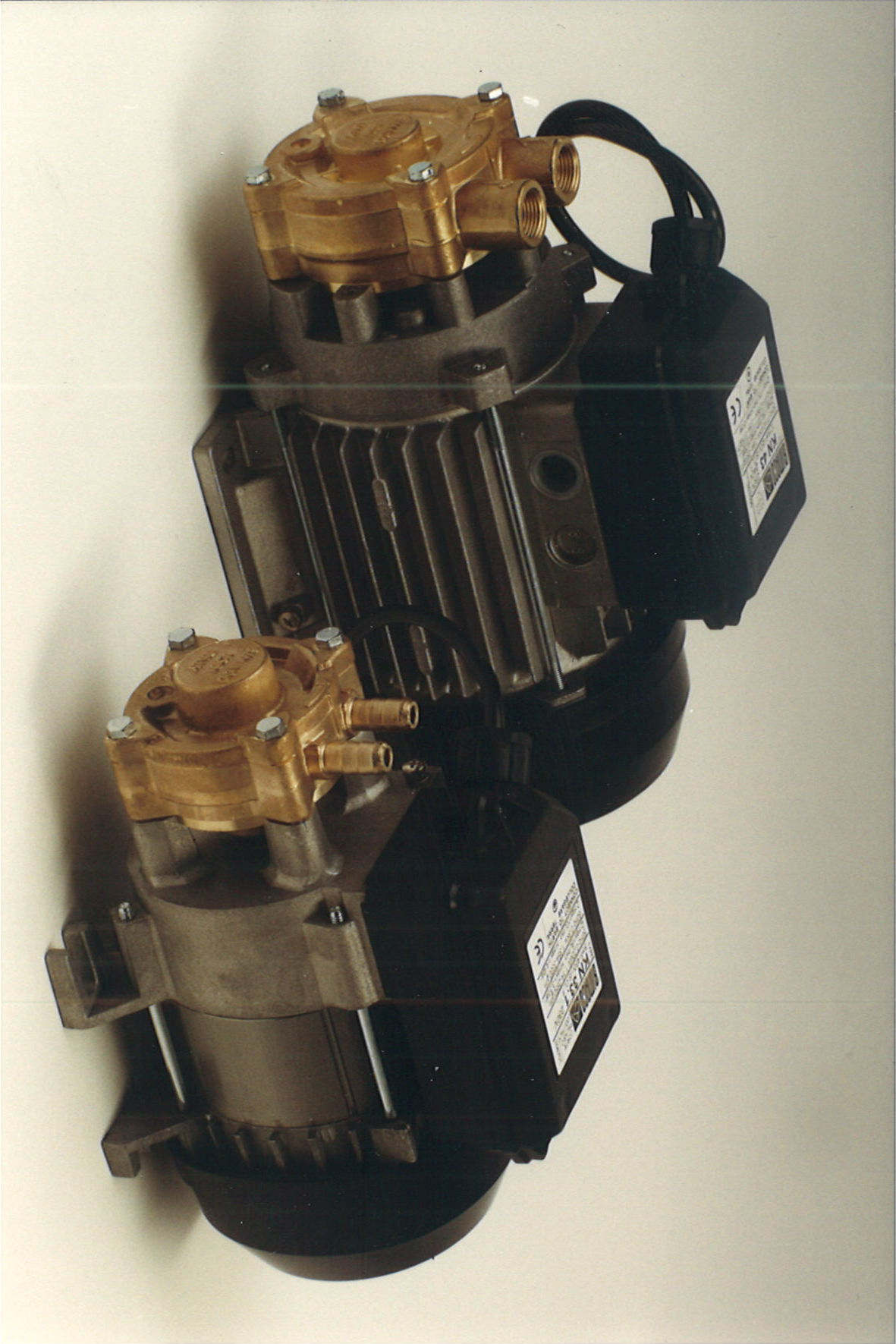

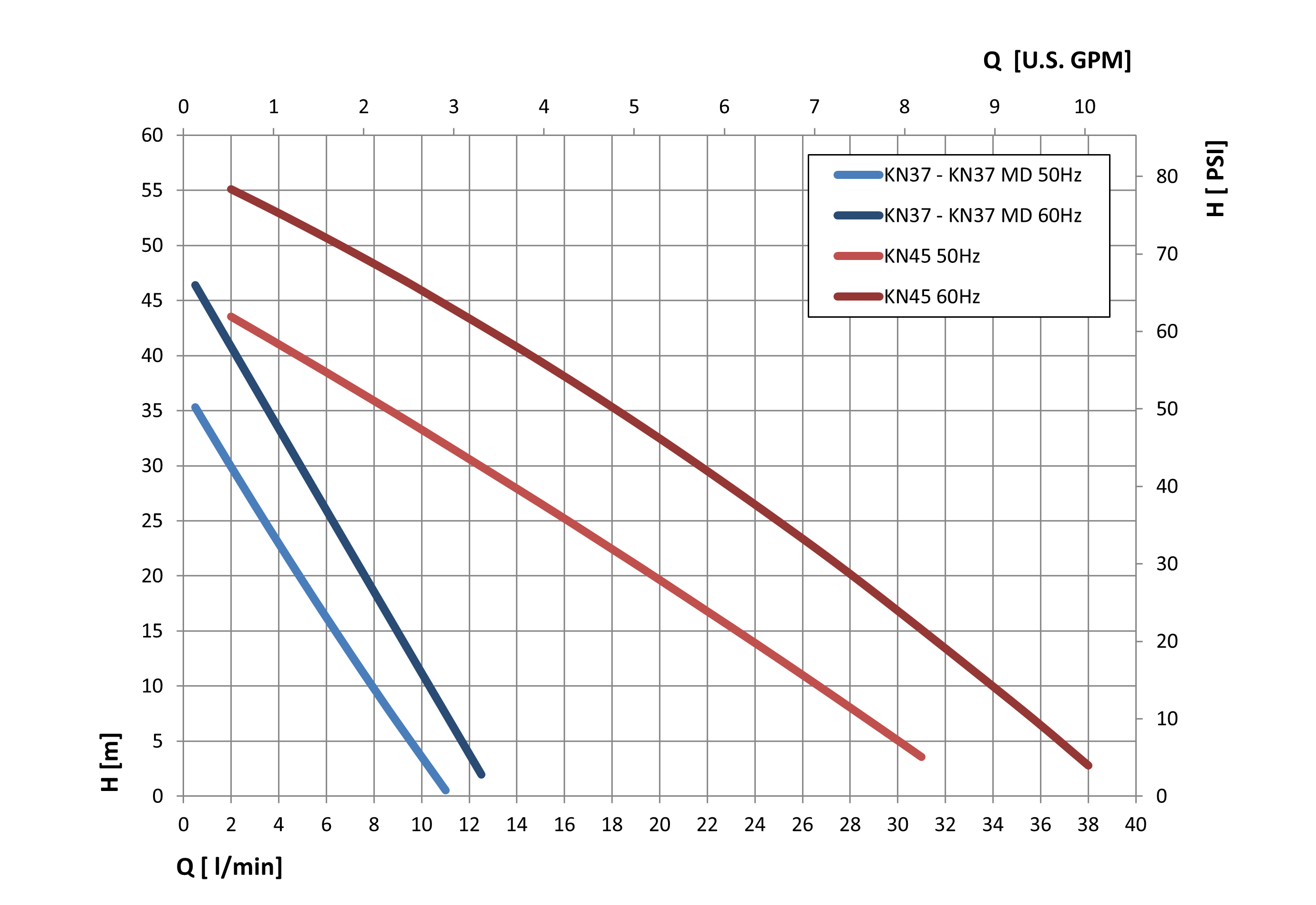

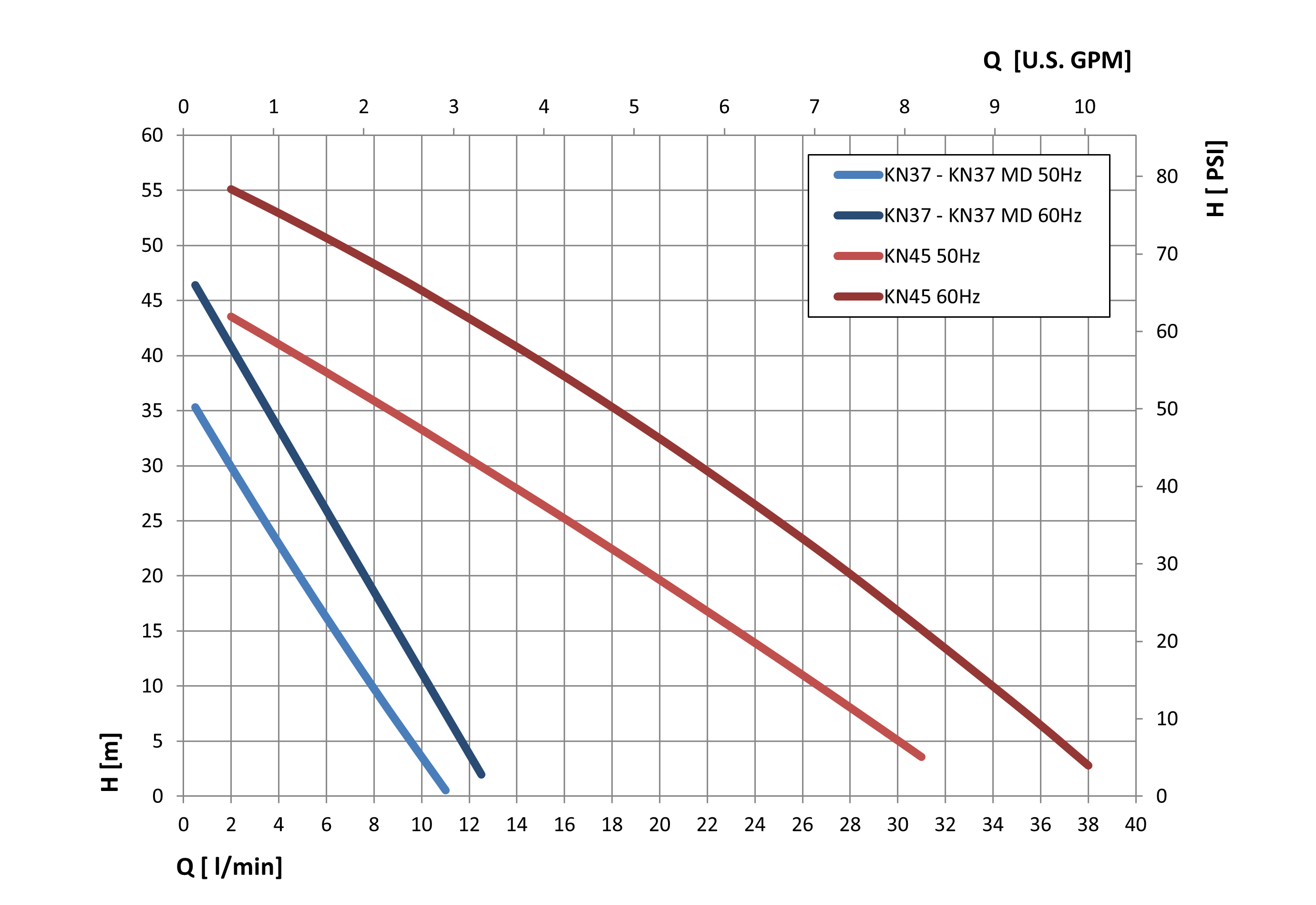

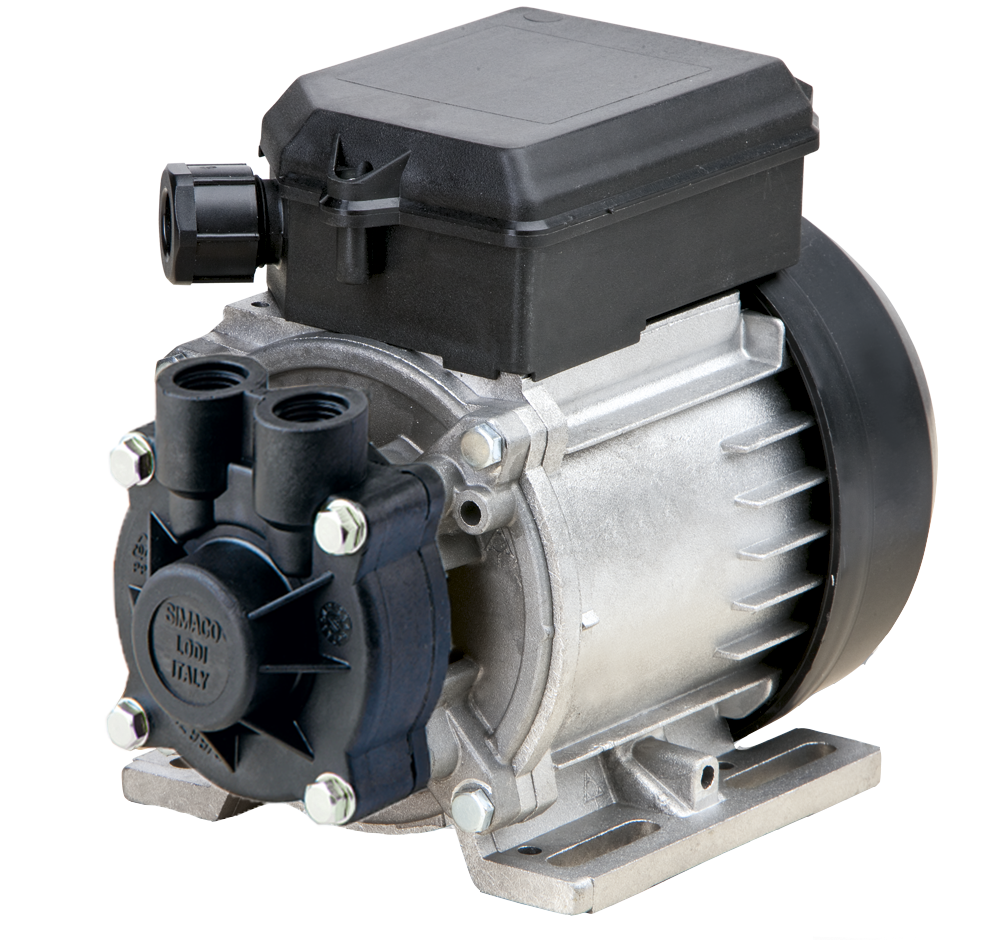

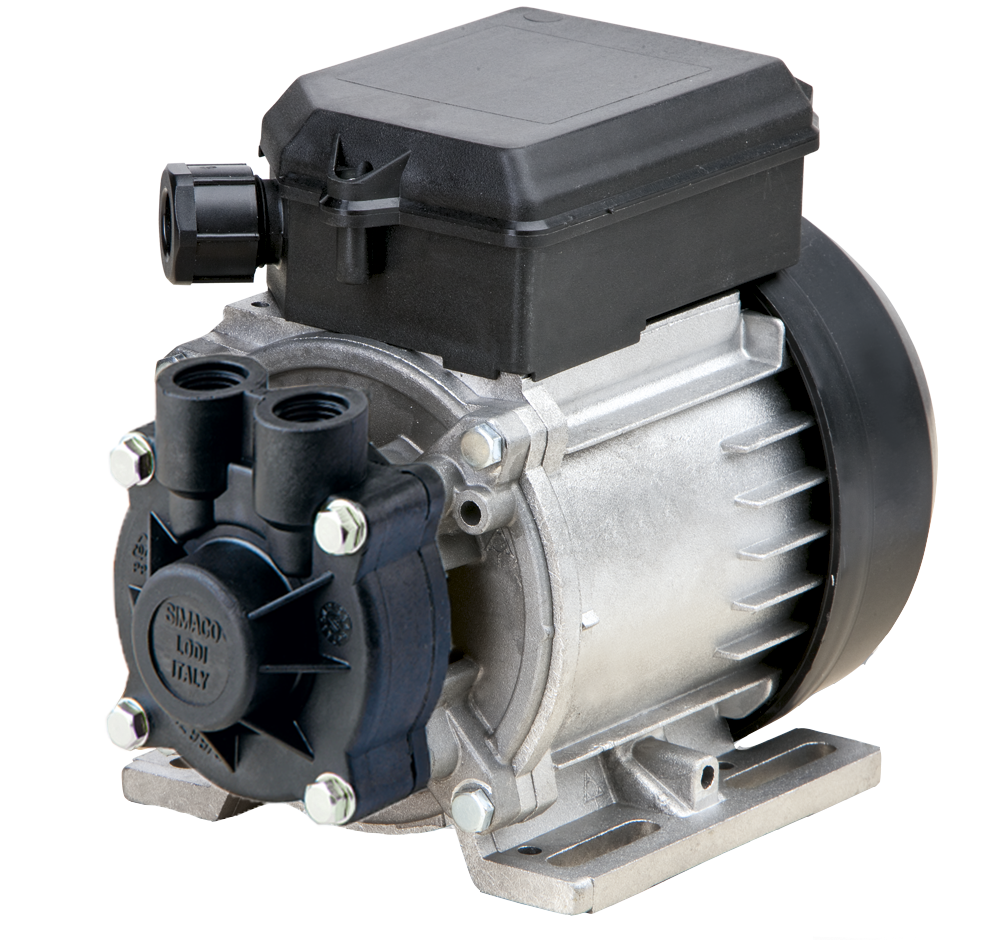

KN is the most successful Simaco product on the market for more than 20 years. Developed for the specific needs of cooling units for the welding sector (MIG, TIG and PLASMA systems), these brass electric pumps operate with a peripheral impeller, guaranteeing high heads even at low flow rates. Ideal for increasing or maintaining circulating pressures at medium-low hydraulic flow rates in closed circuit systems, they work with clear, non-aggressive water and dilutions, in which the absence of abrasive suspensions is guaranteed.

HISTORY

Over the years, since the birth of the first model, there have been 3 versions: KN33, KN35 and from 2017 the current KN37 version. Each restyling has seen the product optimized on various aspects: construction quality, hydraulic and electrical efficiency, size reduction. The work of the internal technical office has made it possible to maximize the miniaturization of components, obtaining the most compact electric pump with traditional asynchronous motor on the market for the welding sector. The constant increase in production has never led to a reduction in the quality level of materials and components, indeed, an ever greater search for process quality: from the quality control of the incoming components, on the assembly line, up to the final testing of 100% of the products.

Since its birth in 2017, the third KN37 version alone has over 145 variants sold, which are characterized by motor, coupler layout, mechanical seal and hydraulic characteristics.

FEATURE

KN37 is equipped with a 2-pole Gr. 56 induction motor powered by alternating current (AC) bi-frequency 50 / 60Hz. Many single-phase and three-phase motors already fall into the IE3 efficiency class. SIMACO designs and manufactures the motors of the electric pumps internally, in addition to the standard voltage in the catalog, it is possible to request customizations according to the needs of the reference market. Customizations are also available regarding the motor architecture: the cooling fan and the electrical connection.

In addition, a version with a sensorless DC-24V Brushless motor without fan is available, characterized by reduced dimensions (up to -53% compared to an AC motor) and high level of protection (IP65), which allows use in applications where there is dust, dirt and humidity.

The hydraulic part is made of brass which has good mechanical characteristics and resistance to various chemical agents, allowing it to be used with liquids at a temperature of -20°C / +90°C (with antifreeze). The wide range of coolants on the market does not guarantee excellent adaptability to this type of pump, both in absolute terms and in relation to individual uses. SIMACO's experience in the sector allows to advise customers on this aspect related to the operation of the cooling unit system, of which the electric pump is the cornerstone.

The plastic version called KNP represents an important solution to cope with the problems of electrolytic corrosion triggered by the circulating liquids, to the detriment of the steel components that make up the hydraulic part (motor shaft, key, mechanical seal). By replacing brass with plastic, a variable in the electrolytic circuit is eliminated, ensuring a longer life span of the product.

The pump housings of the KNP series are made of charged PPS (Poliparphenylene Sulphide), a technopolymer for particular uses with remarkable properties of resistance to chemical agents, high temperatures and steam, non-deformable.

The impeller, on the other hand, is made of loaded PEEK (Polyether ether ketone), a technopolymer with excellent mechanical properties and chemical resistance (thermal degradation and in contact with water) which are maintained even at high temperatures.

The most important element of this type of electric pump is the mechanical seal. SIMACO is supplied directly by leading manufacturers on the market, which guarantee a high level of construction quality and materials. Following a period of internal tests and pilot tests with selected customers, it was possible to identify the best mechanical seal to ensure the compatibility of the hydraulic system with a wide range of coolants. The materials that make up the sliding faces ensure optimal resistance to any deposits that may occur in the liquid due to poor maintenance of the cooling unit, preventing the onset of leaks. A wide range of other solutions are also available that can be selected according to the specific needs of the customer.

MAGNETIC DRIVE

In addition to the wide choice of mechanical seals available, in response to the needs of the sector, in 2018 the MD (magnetic drive) version without mechanical seal was introduced, able to virtually reduce the risk of loss and maintenance times to zero.

Thanks to the compact dimensions of the MD-KN37, with only 8 mm more than the KN37 model, it can be replaced on any machine without having to review or modify the existing structure.

ACCESSORIES

SIMACO offers its customers a series of accessories to complete the range of products for the welding sector.

Lamellar heat exchangers with copper or stainless steel pipes, made according to the customer's design.

White ABS tanks with capacities of 5, 8 and 10 liters, also available with customized geometries based on the customer's design.

Flow switches for liquids that allow to regulate and signal the flow in a pipe for the control of electric pumps.

Write an email to your sales representative or to info@simacosrl.it for more technical or commercial information.

0

OFFICIAL DISTRIBUTORS

0

COUNTRIES SERVED

0

REGISTERED MARKS

0

EUROPEAN PRODUCT PATENTS